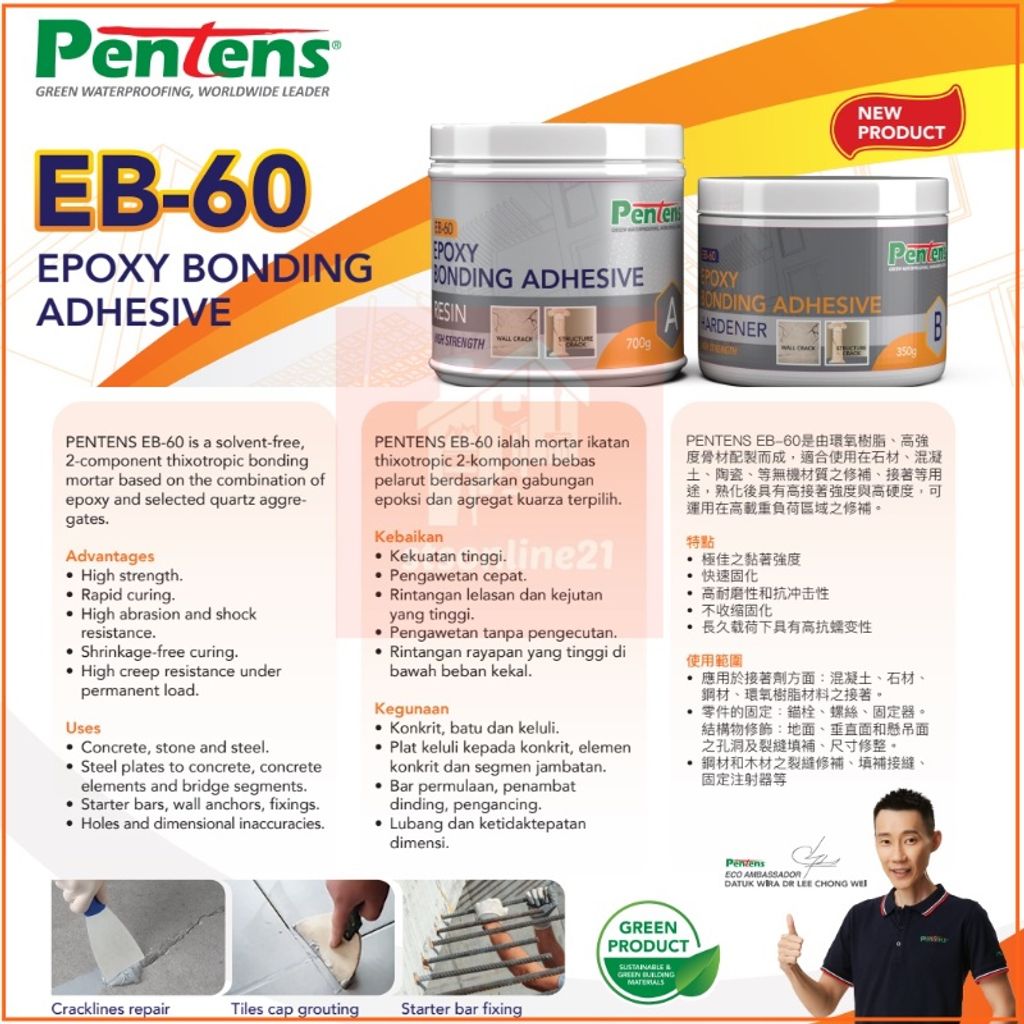

PENTENS EB-60 Epoxy Bonding Adhesive

- Regular price

- RM 24.70

- Sale price

- RM 24.70

- Regular price

-

RM 0.00

Share

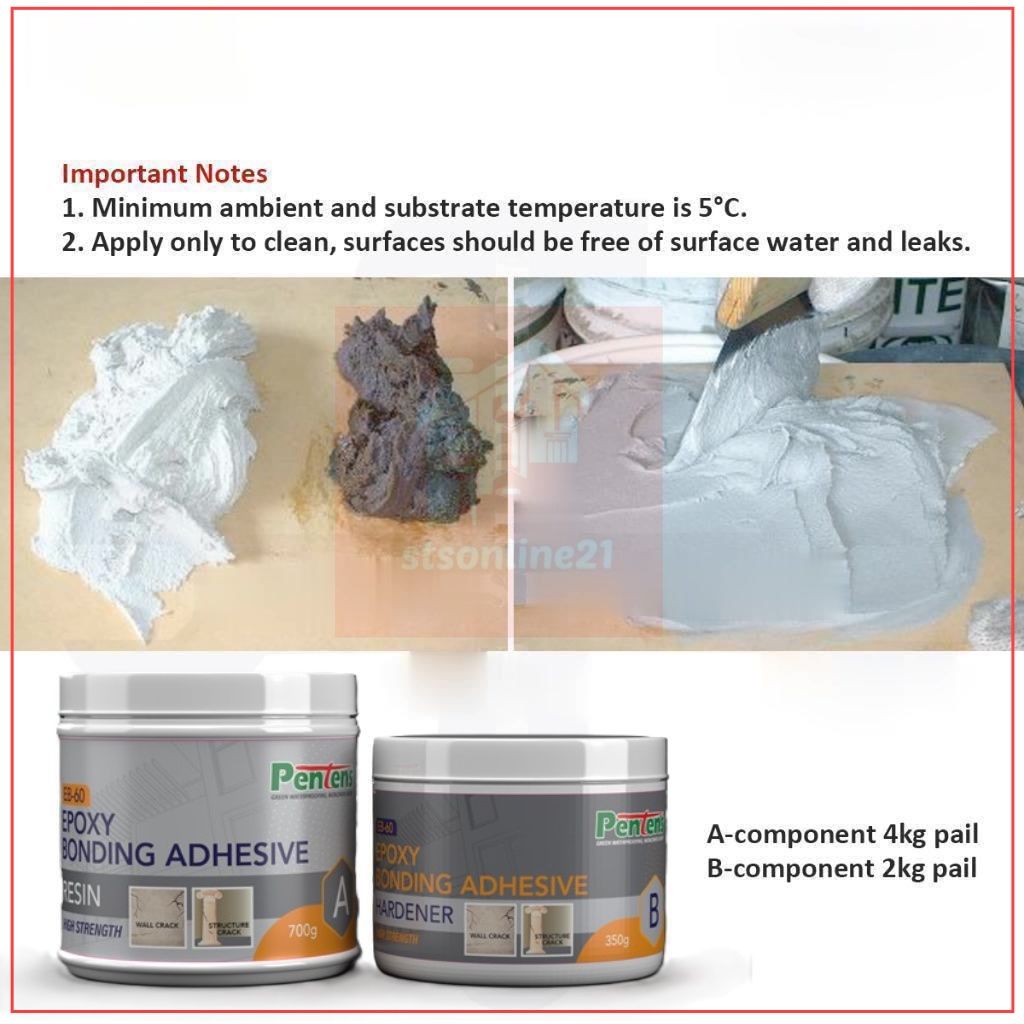

PENTENS EB-60 Epoxy Bonding Adhesive (A:700gm + B:350gm)

PENTENS EB-60: Revolutionize Your Construction with Unmatched Bonding Strength

PENTENS EB-60 stands as a testament to innovation in the construction materials industry. Not only does it offer a powerful, solvent-free solution that prioritizes environmental health, but its thixotropic nature ensures ease of application in a variety of settings. Whether it’s commercial or residential projects, PENTENS EB-60 guarantees a seamless bonding experience that translates into long-lasting and durable constructions. Choose PENTENS EB-60 to elevate your projects to new heights of excellence and durability.

Uses

As an adhesive for bonding reinforcement, adhesive mortar to:

- Concrete, stone

- Steel

- Epoxy

For structural bonding of:

- Steel plates to concrete

- Concrete elements

- Bridge segments

For anchoring of:

- Starter bars

- Wall anchors

- Fixings, etc.

For vertical and overhead filling of:

- Holes

- Dimensional inaccuracies, etc.

Advantages

- High strength

- Can be applied to slightly damp concrete surfaces

- Non-sag in vertical and overhead applications

- Sets without tackiness, even in high atmospheric humidity

- Solvent free

- Rapid curing

- High creep resistance under permanent load

- High mechanical strength

- High abrasion and shock resistance

- Shrinkage-free curing

- Easy to mix and apply

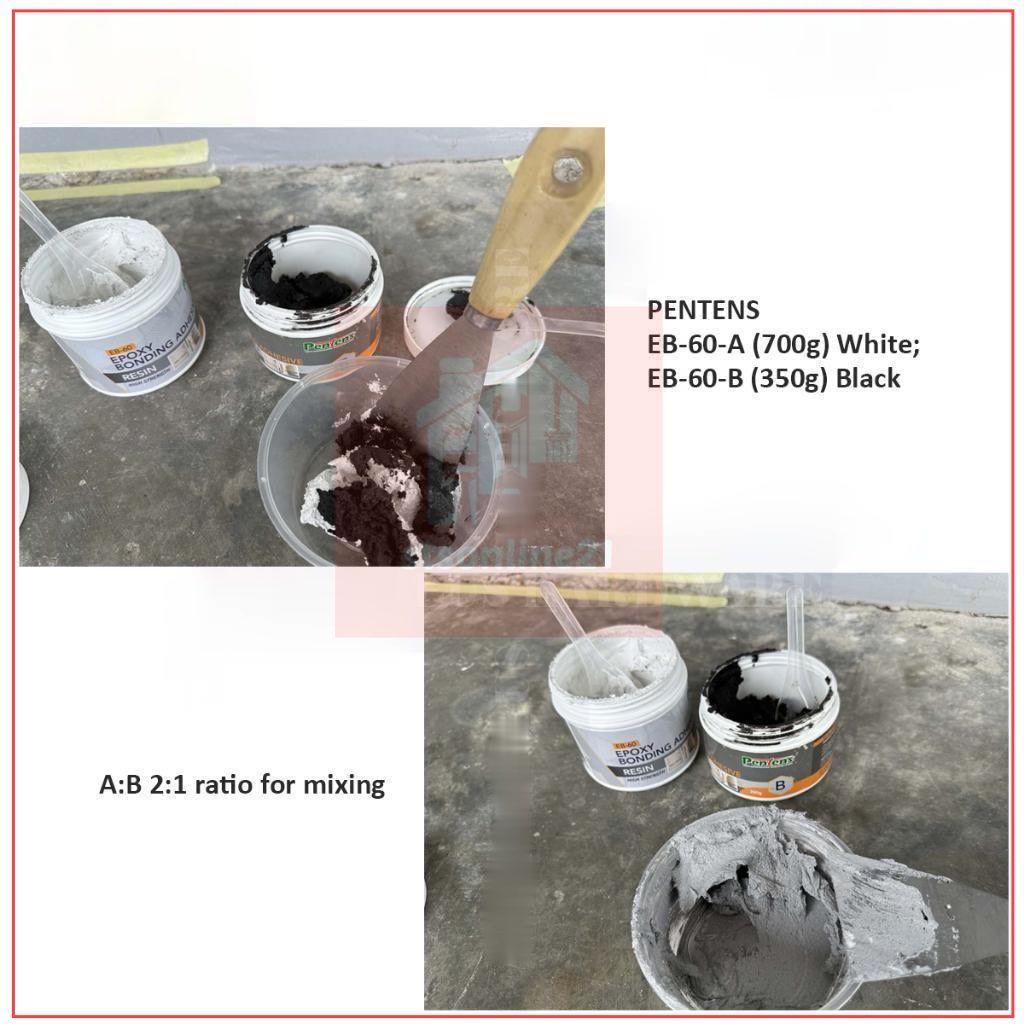

- Components come in different colors so that homogeneity of mix is easy to check

Instruction for UseSubstrate preparation

The surface to be coated must be level, with steps and formwork marks not greater than 0.5mm. After cleaning, remove all dust from the surface with an industrial vacuum cleaner.

Concrete

- Clean, free from oil and grease, dry and no loose particles or laitance.

- Concrete age, depending on climate, must be minimum 3 to 6 weeks.

- Preparation: Blast-clean, scabble or grind.

Timber

- Clean, free from grease and oil, no loose particles.

- Preparation: Blast-clean or grind.

Steel

- Free from grease, oil, rust, scale and rolling “skin”.

- Preparation, sandblast, beware of condensation.

- If the cleaned steel is not bonded immediately, the surface must be given one coat of PENTENS E-008 solvent free epoxy primer to protect it from further corrosion. Consumption is approximately 0.3kg/m2.

Mixing

Stir the material well in the original container. Add component B to component A. Mix with an electric hand mixer for about 1 minutes to a uniform appearance at low speed (maximum 500 rpm) so that as little air as possible is entrained. The pot life of PENTENS EB-60 begins when the resin and hardener are mixed. It is shorter at high temperatures and longer at low temperatures. The greater the quantity mixed, the shorter the pot life. To obtain longer workability at high temperatures, the mixed adhesive may be divided into portions. Another method is to chill component A and B before mixing.

Mixing ratio

PENTENS EB-60 component A:B=2:1 (parts by weight). A correct ratio must be maintained by weighing each component.